In just two weeks, the Italian automaker has successfully used 3D printing technology to design, produce and validate the breathing apparatuses.

Whilst the local and global fashion industry have made numerous headlines for their contribution to the fight against COVID-19, automakers are also jumping on the bandwagon to lend a hand.

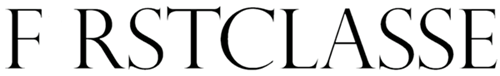

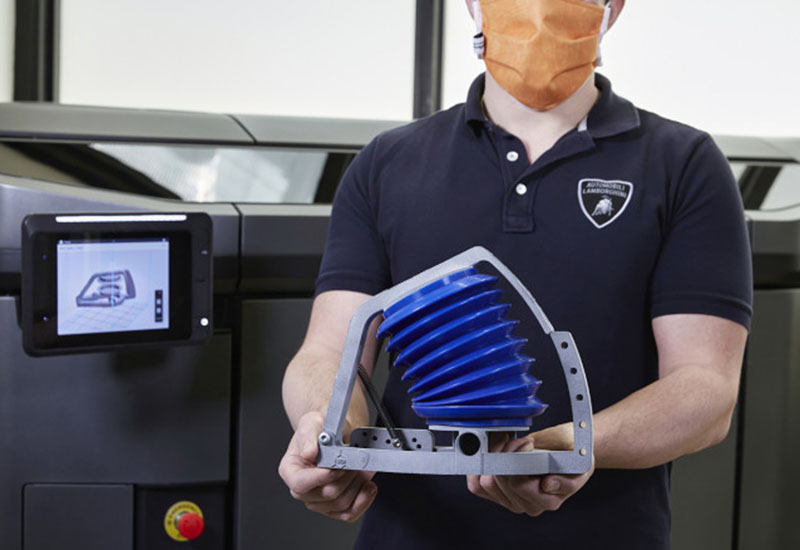

After opening its production facility to manufacture masks and face shields for medical frontliners, Lamborghini has recently announced that it is offering resources and equipment from its Research and Development Department for the co-engineering and production of ‘mechanical lungs’ that function as breathing simulators. This move will serve to support SIARE Engineering International Group, a leading Italian pulmonary respirator manufacturer.

The mechanical lungs will be used by testing personnel to conduct initial evaluative tests of a ventilator’s performance before its final testing stage.

In just two weeks, the Italian automaker has successfully used 3D printing technology to design, produce and validate the breathing apparatuses. Currently, the production unit is able to produce 18 breathing simulators per week.

Aside from the simulators, the company is also producing medical visors, which is 3D-printed from polycarbonate. Both equipment are made using the highly-precise HP Jet Fusion 3D 4200 printer with MJF technology.

Aside from the simulators, the company is also producing medical visors, which is 3D-printed from polycarbonate. Both equipment are made using the highly-precise HP Jet Fusion 3D 4200 printer with MJF technology.

Meanwhile, Lamborghini’s repurposed Sant’Agata manufacturing plant has led to a production of 1,000 masks per day – all of which are donated to a hospital in Bologna.

Photos: Lamborghini